The devastation that we see around us today caused by the second wave of COVID-19 in the country, is not just because of the rates of contagion and the virulence of the disease, but also — and perhaps, more significantly — because of the crunch in life-saving resources. Especially something we have always taken for granted — Oxygen.

But why did the country run short of oxygen and have we been able to find solutions to tide over the shortage?

Although oxygen is the element primarily responsible for sustaining life on planet Earth and constitutes 21% of the atmosphere, oxygen in a purer state is required for a number of applications which can be broadly grouped into two categories.

- Industrial uses – Oxygen purified to 80% and over finds application in multiple industries ranging from steel manufacturing to cutting torches and fabrication.

- Medical uses – Oxygen purified to 90% and above is a vital part of hospital infrastructure and finds application in multiple medical situations to improve oxygenation in tissues, assist breathing in patients etc. Various estimates put the pre-COVID total oxygen usage at approximately 75% -80% industrial and 20-25% medical.

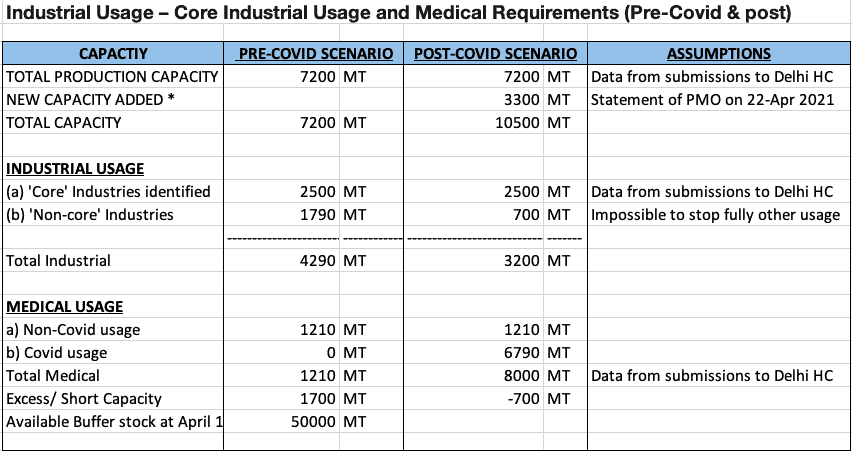

India had, at the time of writing, a production capacity of approximately 7200 MT. However the production capacity is not spread evenly. Eight states, Maharashtra, Gujarat, Jharkhand, Odisha, Tamil Nadu, Karnataka, Kerala and West Bengal account for nearly 80% of India’s total oxygen production.

The primary manufacturing method used for extracting oxygen from air is liquefaction and fractional distillation. Of late, oxygen concentrators have been deployed to provide oxygen for medical purposes, but oxygen concentrators have not demonstrated their capacity to be scaled up to large quantities.

Core industrial usage and medical requirements (Pre-COVID & post)

In a recent hearing, the central government had made certain submissions before the Delhi High Court. On that basis, it is possible to group together the pre-COVID and post-COVID scenario into the single table that shows where things stood on April 22nd.

But there are several problems with this data and the assumptions that have gone into it:

- From the data above, it is clear that oxygen will run out within around 71 days from April 1st without further measures.

- The exploding number of COVID-19 cases would mean that the total COVID-related medical oxygen usage would probably climb quite drastically and the usage figure shown – of 6790 MT – may already be quite out of date when you read this.

- Enhancement of oxygen manufacturing capacity does not translate into seamless availability of oxygen at the locations required because of the poor infrastructure available at hospitals, transport systems etc.

The truth is that we are in a dynamic, evolving situation and we are, in that sense, pursuing a moving target. Two things are happening: the supply is rapidly increasing due to extraordinary one time measures, including imports from various countries. But then demand is also rocketing up.

Read more: Shortage of oxygen a big challenge for Pune hospitals; here’s how they are coping

Ways to transport and manage oxygen supply at individual sites

Liquid oxygen storage tanks at the hospital premises are the most efficient — liquid oxygen would be transported in cryogenic containers to the liquid tanks, Oxygen is then converted into gaseous form and piped to the individual wards/ rooms/ operation theatres for usage.

Where there are smaller hospitals/medical centres which do not have liquid oxygen storage tank facility, the only option is to use oxygen cylinders, where two further problems result:

- Substantial wastage of oxygen: Each cylinder loses around 5-10% due to lack of pressure as the cylinder empties

- Lack of adequate cylinder manufacturing capacity to cope with demand explosion

Oxygen cylinders vs concentrators

For mild to moderately symptomatic COVID patients, especially those in home isolation, oxygen concentrators are proving to be an effective alternative. These take in ambient air, primarily made up of oxygen and nitrogen, filter it to extract the oxygen and release the nitrogen back into the air. The device then works on the oxygen to make it fit for medical use.

Given the finite capacity limits of cylinders and the current shortage, oxygen concentrators are in high demand. However, they need continuous power supply and can deliver only 5-10 litres of oxygen per minute, which makes it inadequate for use in critical COVID cases.

Not surprisingly, concentrators are selling at a premium now. Reports such as this suggest that a concentrator sells at anything between Rs 40000-Rs 90000, but that is largely a one-time investment. However, it is important to check the purity of the oxygen that the machine delivers; experts have been quoted to emphasise that the oxygen from these machines at 5 litres per minute should be at least 92-95% pure.

The real crunch, however, is again supply as there are not enough domestic manufacturers to meet the demand that exists under the current circumstances. It is a market largely supplied by imports. A recent press release from the government says that individuals can now acquire oxygen concentrators from abroad for personal use, through post, courier or e-commerce portals, in the list of exempted categories, where customs clearance is to be sought as ”gifts”. This exemption is valid till July 31 2021.

Government focus…

…is presently, therefore, on the following areas:

- Procuring more cryogenic containers to transport liquid oxygen to the liquid storage tanks. We just do not have enough locally. On Apr 25th came the news that Cryogenic containers have been imported from Singapore and Saudi Arabia.

- Asking Industries with captive oxygen manufacturing capability to manufacture oxygen for medical requirements

- Attempting to convert Nitrogen manufacturing facilities into Oxygen manufacturing facilities — this presents its own technical challenges and additional equipment

- Ramping up the overall oxygen production in the country to cope with this demand explosion. But this won’t be easy, as the issue will be on what to do with the excess capacity once the crisis is behind us.

- Ramping up oxygen cylinder manufacturing capacity — this again does not lend itself to quick upscaling

Pic Courtesy: Dr Dhanaji Jadhav

Looking at the five areas listed above, the area of high vulnerability over the next few weeks is likely to shift to smaller cities, where the lack of liquid oxygen storage tanks will make the logistical challenge very dire.

The Karnataka scenario

Karnataka is one of the leading oxygen-producing states with a total oxygen production capacity estimated at 812 MT.

However, various news reports show that the situation is far from comfortable due to many factors:

- Demand appears to be far outstripping supply and right now, most of the demand is being met by dipping into the inventory.

- Since oxygen is primarily produced by liquefaction of air, higher ambient temperatures in summer slows down production capacity. The present COVID wave has therefore come at a particularly bad time.

- Various estimates show that the total oxygen demand could climb as high as 1500 MT a day (based on a worst case scenario) and that would leave the state vulnerable.

- The Central Govt has ruled out blocking export to neighbouring states and many gas plants in Karnataka send Oxygen to Tamil Nadu and Andhra Pradesh.

Read more: Where do Bengaluru hospitals get their oxygen supply from?

Pricing of oxygen

Manufacturers of oxygen sell their product at market rates to industries and private hospitals. Government hospitals and facilities have their own longer term purchasing procedures. However, like any industry, oxygen manufacturers face their own share of problems:

- Seasonality: Oxygen requirements peak during January to March which is the peak industrial season. Weather also has a huge effect on Oxygen production. Warmer temperatures bring down production drastically (since air has to be liquefied from higher temperatures).

- Lack of any special incentive/support from the government: Even in times of crisis, there is no special effort made by the government to support oxygen producers by providing incentives to enhance production by additional investments. On the contrary, they often become the convenient scapegoat for a wider problem.

- Bureaucratic delays: Over the past two days it was reported that thousands of oxygen concentrators were lying uncleared at Delhi customs due to technical paper work related issues. Red tape does not appear to take a back seat even amidst this unprecedented crisis.

There are definite signs that the efforts being undertaken are in the process of transforming the primary challenge for oxygen requirements from a demand-supply mismatch to a logistical challenge (getting oxygen produced at a location to the locations where demand is being generated). This situation was highlighted by former Union Finance Minister P Chidambaram, giving a specific example of oxygen manufactured at a location in Tamil Nadu being directed to Telangana over 600 km away, while at the same time a location requiring oxygen just 30 km away in Tamil Nadu itself was directed to procure the same from Bellary in Karnataka — a distance of over 900 km! These logistical issues need to be sorted out to improve delivery to the hospitals and care centres that are in dire need of this life saving gas.

Covid usage data is based on Governments own assessment which has been struck down by Supreme Court. Govt assessed Delhi’s need as 400 MT but Supreme court ordered it to give 700 MT. Same with Karnataka. Thus Covid Usage should be around 16000 MT.