Bengaluru has a large, expanding number of self-contained, gated communities (GC) comprising either a series of apartment blocks or individual houses. Utilities such as power and water in these communities are exclusive to their residents. The transformer is the most critical part of the electrical installation in a residential community. This article explains the various steps in their installation and maintenance.

The role of transformers

The electricity we get in our homes is generated at very high voltage and then transmitted to us through electric lines over long distances. Since the appliances in our homes operate at low voltage, this high-voltage electricity needs to be converted to low-voltage electricity. Distribution transformers carry out this last-mile voltage conversion.

Note: For the purposes of this article, it is presumed that a gated community has a minimum area of 7.5 acres and/or sanctioned load above 150kW; it would include 100 or more units, having a High Tension (HT, say 11kV)) power supply. Individual dwellings that get Low Tension (LT) supply are metered under LT2A category and common area utilities like Sewage Treatment Plant (STP) at LT3.

The steps followed by the builder during the installation of a transformer are:

- Sizing and selection

- Drawing documents for statutory approvals, procurement process (Tendering) and consultants’ approvals

- Testing at factory

- Erection, testing and commissioning at site

- Operation and maintenance (O&M)

All the above steps have an effect on the capital expenditure (capex), quality of power, operation and maintenance (O&M), efficiency and life of the transformer.

Read more: How to apply for a BESCOM connection

Sizing and selection of transformers

Sizing is done as per the rules of the Electricity Board (EB). There are two ways in which the Electricity Board sanctions power to such communities:

Option 1: HT supply and single point HT Billing

- Electrical Installation is by GC. O&M has to be done by the GC, by employing HT-certified operators or contractors. This is typically used by commercial buildings and tech parks. HT Billing is economical compared to LT Billing.

- The ownership of the transformer and the entire electrical installation rests with the GC; EB is responsible up to the HT Metering Cubicle only. The installation is considered an HT Consumer.

- The transformer can have Auto Voltage Correction, which regulates the voltage, which is good for the consumers.

- EB personnel need not enter the GC.

Option 2: HT supply and individual LT Billing

- Electrical Installation is by GC. The GC has to do the O&M only for the first year after installation. Then it has to be handed over to EB who will then be responsible for the O&M. (However, in reality, many apartments proactively ensure preventive maintenance is carried out).

- EB is responsible for each LT Meter.

- The installation is considered an LT Consumer.

- EB personnel have to be provided free, unhindered access up to each LT Meter.

- Dependency on EB to attend to power supply faults (within the GC).

Selection of the transformer, in terms of copper/aluminium winding, brand, efficiency, etc. should be done on the recommendation of the Electrical Consultant.

In reality, builders/developers generally decide on the choice of transformer based on capex.

Read more: Have STP and fire hydrant in your apartment? This is what BESCOM can charge

Operation and maintenance requirements

The following are the engineering considerations for O and M of transformers:

- Location: Transformer shall be at a level so as to avoid flooding, damage by falling, piling up of dried leaves (leading to fire hazard), branches of trees, vegetation growth, animals, vermin, damage and theft, dumping of garbage and debris, etc.

- Civil/Structural/Mechanical: Transformer plinth (foundation) design shall be as per specifications given by the Structural Consultant. Construction shall be carried out as per standard practice. Space shall be provided with 40mm stone jelly (aggregate) to a height of 100 mm. MS members of the transformer and fence should be protected against rusting and have concrete pedestals if required. Painting should be done annually. Check Danger Board, No Smoking boards, locked gates, etc. Nomenclature for Sub Station e.g., Substation No. ..:11/0.415 kV, ….kVA.

Documentation for transformers

The Management Committee (MC) should ensure the following drawings and documents are handed over:

- Statutory approvals from EB and CEIG (Chief Electrical Inspectorate to the Government) and others like Panchayat, BIAAPA, BMRDA, BDA, etc.

- Main Single Line Diagram, Equipment catalogues, suppliers’ contact details, technical specifications, factory test reports, and site test reports of all equipment and earth pit resistance.

- For transformers: HV test reports, Oil BDV (Break Down Voltage), protective relay tests, Silica Gel colour.

- EB’s MRT (Meter and Relay Test Division) test reports

All these documents should be available in hard copy (prints) and soft copy in the substation or estate office. They shall be reviewed by an external agency annually. There are agencies certified by CEIG for such testing. The electrical O&M staff should be trained to read, refer, record and maintain (update) electrical records.

All operations in the HT Substation should be carried out by a licensed HT technician or Class A Licensed Electrical Contractor (LEC). For voltages higher than 11kV, LEC should be Super Grade. Safety items for normal O and M -HT Gloves, HT Mat, etc must be provided and checked on a monthly basis. LEC shall carry and use safety items like 5kV Meggar, HT Earthing Rod, etc.

Regular checks of the transformer

Under no circumstance should work on the transformer be done unless :

- It is disconnected from all external electrical circuits and all windings have been properly grounded.

- All flammable objects should be kept well away from the transformer while working.

- Ensure all fire safety equipment in the enclosure is properly maintained.

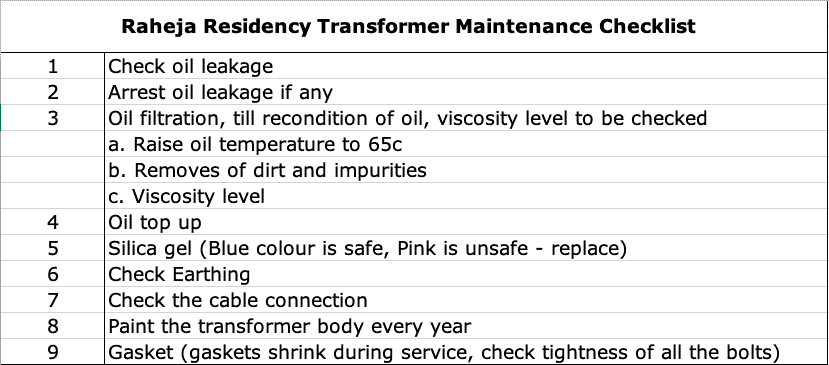

Use checklists and record

Daily

- In the summer season, check transformers’ oil temperature (on random days)

- Before the onset of the rainy season, check the BDV of oil and Silica gel colour

Weekly

- Non-electrical points mentioned above

- In the summer season, check transformers’ oil level

- In the rainy season, check for water flowing through HT yard, falling tree leaves and branches; in rare cases landslide/mudslide or uprooting of trees

Monthly

- Voltage: Ph-Ph, Ph – N and Ph-E, in LT Panels, receiving power from the transformer.

- Current: R, Y, B and N of LT panel.

- In summer: Check transformers’ oil temperature relay operation

- Water the earth pits regularly

- Check for the presence of flammable materials – dried leaves, paper, wood, etc.

Annually

- Statutory annual Inspection as per CEIG: Sizing of switchgear, spacing of equipment, Relay / Protection operations/testing, earth pit resistance, the physical condition of installation, etc.

- Oil filtration and breakdown voltage (BDV)

- Test all transformer protective relays:

- Buchholz, oil temperature trip, earth pits resistance

- Check the tightness of termination using a torque wrench

- Check the physical condition of cables, earth strips

An audit every 5 years by an Electrical Consultant or a certified testing agency is recommended.

Dear Mr. Rao

I am Mr. Vaman working as Facility Manager in Bangalore. I come from non technical background and willing to learn more in MEP. This article is very informative & look forward to more articles in other MEP topics.

Thank You.

Vaman Joshi

Can private commercial multi storied establishment leaving no set back install transformer on foot path