17,422 metric tonnes per day — that’s the staggering amount of trash the Greater Chennai Corporation (GCC) will generate in 30 years. Currently, Chennai produces 6,143 metric tonnes of waste daily, which adds to the growing piles in Kodungaiyur and Perungudi dump yards. Like many other major cities, GCC is struggling to find a sustainable solution for waste management and has proposed a Waste-To-Energy (WTE) plant. However, the experiences of cities like Delhi are testimony to the significant environmental and health impacts of WTE plants.

A recent The New York Times investigative report on the Delhi WTE reveals: “The government promised to incinerate the trash safely in a state-of-the-art plant, turning the waste into electricity in an ingenious bid to tackle two major problems at once. Instead, the government’s answer to its bursting landfills and boundless need for energy is exposing as many as one million people to toxic smoke and ash, according to air and soil samples collected by The New York Times over a five-year period.” The report revealed how basic steps needed to operate safely have been skipped at the Delhi plant to cut costs.

Recently, the Supreme Court also heavily criticised the Delhi Municipal Corporation for violating the Solid Waste Management Rules, 2016.

According to tender documents accessed by Citizen Matters, the waste processed in the upcoming WTE plant would only increase from 3,000 MT/day to 3,600 MT/day in 13 years and remain the same for 30 years. Can this justify the money spent on such a facility and the resultant pollution over the years?

Current tender status of Chennai’s Waste-To-Energy plant

There are several examples of why WTE incineration is not a solution to Chennai’s garbage woes. We have also covered this in an earlier article. However, GCC does not seem to be deterred. It has already floated a tender for the plant and the tender process is underway. Here is a quick look at where Chennai’s WTE stands.

Read more: Women of Ennore are living testimony to the many costs of pollution

The GCC proposes to establish an Integrated Solid Waste Processing Facility (IWPF) at three designated locations: Sathangadu village in Thiruvottiyur, Selavoyal village in Perambur and Chinnasekkadu village in Thiruvottiyur. The IWPF will have three components: WTE plant, compost facility and Bio-CNG facility.

These facilities will process solid waste generated from Zone 1 to Zone 8 and non-recyclable (segregated) waste that can be incinerated, from Zone 9 to Zone 15. The project will operate under the Design-Build-Finance-Operate-Transfer (DBFOT) model of Public Private Partnership (PPP) and last for 20 years.

The GCC floated the tender in March 2024. Two companies — Delhi MSW Solutions and Brij Gopal Construction Company (BGCC) — filed the bids.

The evaluation process

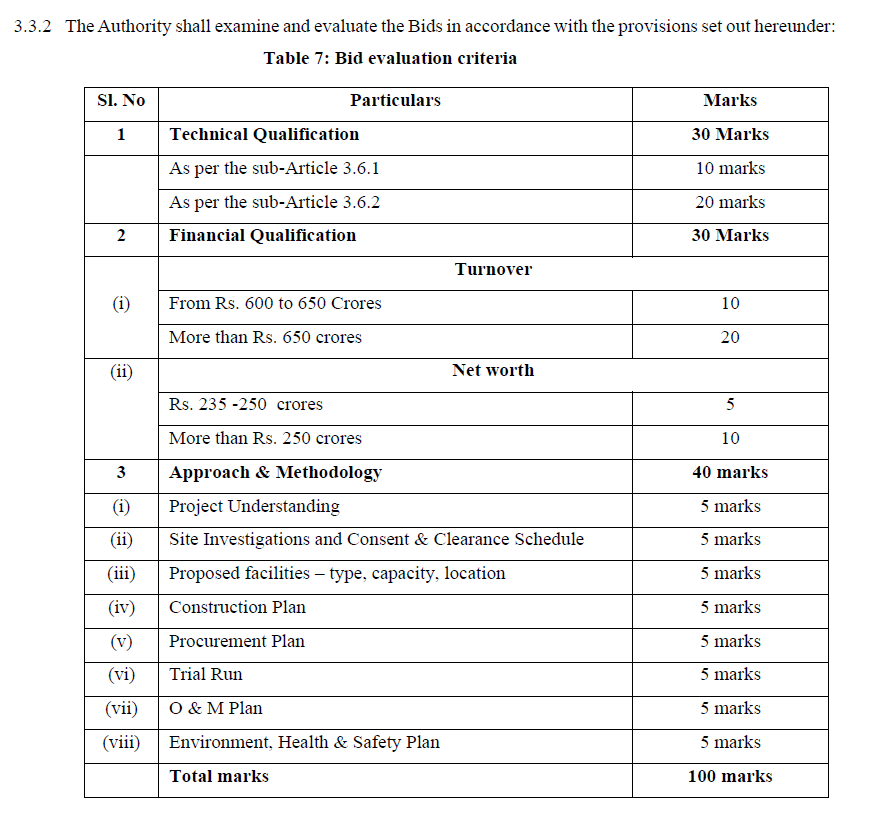

- Stage 1: Bids found to be substantially responsive in the first stage will be evaluated in the second stage.

- Stage 2: The bids shall be evaluated on their technical and financial qualifications. The approach and methodology (IIOP) submitted by the bidders for undertaking the project would be evaluated. Only those bidders who qualify in the second stage will be shortlisted and considered for the third stage, i.e., the opening of the financial bid.

- Stage 3: The online financial bid would be opened, evaluated and negotiated to identify the successful bidder.

The bidder, who is technically qualified and quotes the lowest Aggregate Annual Processing Fee (AAPF) will be awarded the project. (The AAPF is the fee that the authority pays to the Concessionaire for designing, financing, constructing, operating, and maintaining the project facilities.)

The technical bid was opened on August 19 2024. Following this, the financial bid was opened on October 23 2024. While both bidders have qualified for the technical bid, evaluation for the financial bid is underway.

According to the BOQ comparative chart of the financial bid opening summary, Delhi MSW Solutions has quoted Rs 190.79 crore while BGCC has quoted Rs 208.86 crore as the aggregate annual processing fee.

Read more: Ennore power plants violate emission norms, pose serious health risks: Study

What do we know about the bidders?

BGCC is a Haryana-based contracting company with no experience in solid waste management. The company has mostly worked on infrastructure projects such as road and highway construction, sewerage, stormwater drains, and housing projects in Haryana and Delhi.

The National Company Law Tribunal (NCLT), New Delhi Bench in July 2023, while deciding on a petition filed in M/s Geocon Infra Pvt. Ltd. v M/S. Brij Gopal Construction Company initiated a Corporate Insolvency Resolution Process (CIRP) against Brij Gopal Construction Company. However, it was soon withdrawn.

On the other hand, Delhi MSW Solutions is part of Re Sustainability Limited, an integrated resource management company. The firm operates a WTE plant in Delhi’s Bawana Industrial Area (Delhi). “Delhi MSW Solutions is a repeat violator of environmental standards. The Delhi Pollution Control Committee (DPCC) has slapped a fine of Rs 5 lakh on the company for releasing 490% more dioxins and furans than the prescribed limit and burning a higher quantity of waste than permitted while generating less electricity than the mandated 24 MW. Also, the PM10 levels were twice the prescribed limits of 100 μg/m3,” notes DK Chythenyen from the Centre for Financial Accountability (CFA).

Issues with project cost

| Delhi (Narela-Bawana, run by Delhi MSW Solutions) | Chennai (Kodungaiyur) | |

| WTE Cost | Rs 458-crore | Rs 1,026.41 crore |

| Power generation capacity | 24 MW | 31 MW |

| Waste processing capacity (metric tonnes/day) | 2000 MT/Day | 2100 MT/Day |

| Cost/MW | Rs 16.36 crore/MW | Rs 33 crore/MW (Approx) |

“At Rs 33 crore/MW, the WTE incineration project is exorbitantly high, making it the most expensive form of electricity in the country. It is almost four times the cost of a thermal power plant and thrice the cost of a nuclear power plant. The WTE incineration project constructed in Delhi was proposed at half the price of Rs 16.3 crore/MW. The recently commissioned WTE incineration plant in Ahmedabad spends only about Rs 25 crore/MW,” notes Chythenyen.

“The cost may differ from city to city. However, the ability of GCC to afford projects worth over Rs 1,000 crore should be questioned,” notes Radhakrishnan from voluntary organisation Arappor Iyakkam.

North Chennai can no longer handle red-category industries

In an affidavit submitted to the Supreme Court in September, the Delhi Municipal Corporation acknowledged that only 55% of waste generated in the municipal wards was being segregated at source.

The GCC claims to have achieved 65% of house-to-house garbage collection in the city. Former GCC Commissioner J Radhakrishnan in an interview with Citizen Matters had said that of the 65%, about 35% to 45% were segregated at source.

However, the Chennai Climate Action Plant (CCAP) report based on 204 stakeholder consultations and interactions, has advised against WTE plants. It says, “Out of the total MSW that Chennai collects, GCC processes only 20% of it and dumps the rest 80% in the landfills.”

Not a feasible option

Notably, CSIR-NEERI, in its report to the National Green Tribunal on the operations of WTE plants, concluded that any plant based on mass burning of mixed waste was not a feasible option for India.

According to the Central Pollution Control Board classification, WTE incineration is a ‘red category’ industry, which has one of the highest Pollution Index scores (>60). That’s because of flue gas discharges such as SOx, NOx, HCL, PM, Dioxins and Furans, water effluent with toxic pollutants and hazardous bottom/fly ash that needs to be disposed of in a secured scientific landfill.

North Chennai is already home to over 20 red-category industries. Based on the directions from the Southern Bench of the National Green Tribunal (NGT), the Tamil Nadu Pollution Control Board (TNPCB) has commenced a pollution load-carrying capacity study in the Manali industrial region. Even before the study is over, the GCC has floated the tender for yet another red-category industry that would potentially worsen the situation. “Given the significant impact of the WTE and its history of not being successful in any other city, GCC should reconsider this project,” says Radhakrishnan.

A fundamental difference is that the Delhi project is not an integrated solid waste management project