[In Part 1 of this series, we looked at the ongoing practice of manual scavenging in Bengaluru, even though it was officially banned in 1993. Part 2 delved into the main reason for its continuation, which is the lack of awareness about the operation and maintenance of sewage treatment plants (STPs)]

In part 3, we explore the functioning of STPs in Bengaluru and how their effectiveness can be enhanced for both the betterment of the environment and to eliminate manual scavenging.

Why are STPs important?

According to Ananth S. Kodavasal, director at Ecotech, who also formulated the STP guide for Karnataka State Pollution Control Board (KSPCB), a good STP should do three things. Firstly, it should be able to efficiently manage the volume of sewage it is designed to handle. Secondly, It should produce treated water that complies with quality standards, which is mandated for recycling and reuse.

Thirdly, since sewage treatment is a biological process, the growth of microbes and bacteria occurs. It is important to control the bacteria population. “Therefore, you should be able to correctly and completely handle the excess solids or sludge in your house. So, three things are required: quantity, quality and proper management of sludge and solid handling,” says Ananth.

Within the apartment complex, STP is the only piece of infrastructure that generates revenue by returning invested money. “In Phoenix Mall, out of five lakh litres, we recycle four lakh litres every day, resulting in savings of close to Rs 50,000 per day,” says Ananth. However, STPs receive minimal attention since they deal with sewage and are mostly located away from public view.

How do STPs function?

STPs broadly fall under two categories: aerobic and anaerobic. Aerobic uses air to accelerate the process of the treatment of sewage water, whereas anaerobic relies on the natural process of substance breakdown, which is more time-consuming.

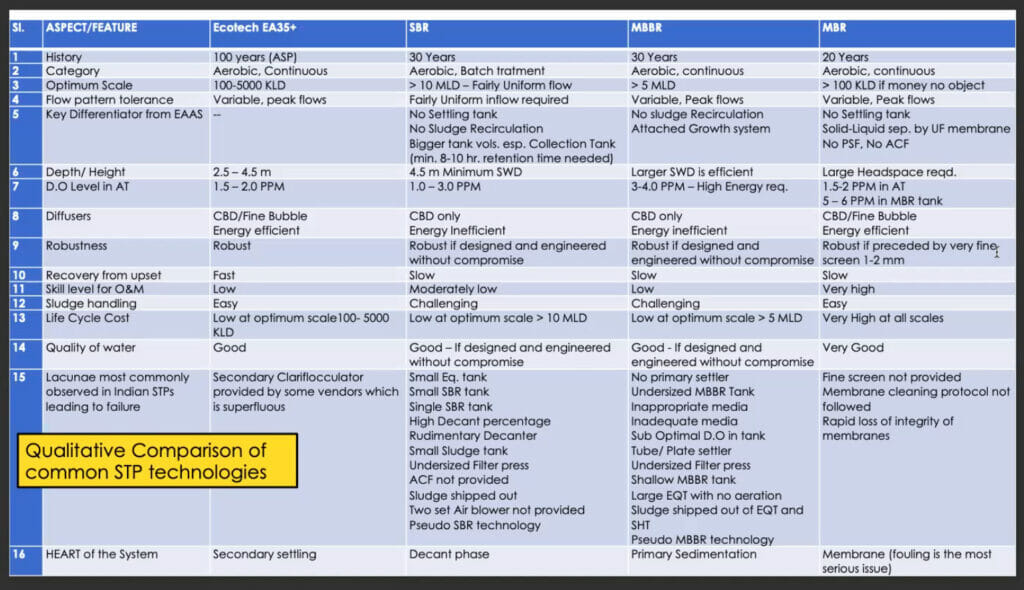

Most of the STPs in Bengaluru are aerobic. However, there have been new developments in anaerobic STPs and a combination of aerobic and anaerobic types. “Just like there are different technologies in automobiles, there are different models in STPs. Depending on the size and scale of a treatment plant, there are only one or two optimum technologies best suited for its requirements,” says Ananth.

As per the KSPCB guidelines, the approved technologies mentioned by the KSPCB are:

- Activated Sludge Process(ASP) only in the case where sewage generated is 500 KL and above

- Sequential Batch Reactor(SBR)

- Membrane Bio Reactor (MBR)

- Moving Bed Bio Reactor (MBBR) / Fluidized Aerobic Bed rector (FAB)

While all of these technologies are aerobic, anaerobic technologies have also proven to function as efficiently as their aerobic counterparts, and at a lower cost.

One size does not fit all

The primary issue is the lack of knowledge among experts themselves regarding which technology is suitable for which infrastructure and type of STP. “I call them ‘jumbled up fake technologies,’ as the consultants and practitioners of STP designs are not fully aware of the nuances of these technologies and end up mixing them,” adds Ananth.

Most of the sources Citizen Matters spoke to believe that even though Bengaluru is the hub for all technological developments in STPs, there has not been enough research and analysis about their practical applications.

“We cannot adopt Western models blindly, due to the difference in type and severity of sewage spanned geographically since people’s diet varies from country to country. The primary cause for STP failure is the indiscriminate use of Ctrl-C and Ctrl-V of technologies without research. And we don’t know if it actually works or not. And we don’t know what to do if it stops working,” says Sunil Ballal, co-founder and director of Aquasphere Greentech Solutions.

Each model comes with its own set of pros and cons, along with specific regions where it is applicable. This has to be studied by designers and builders before installation. According to Ananth, SBR and MBBR are more suitable and advantageous for larger municipal scales, for instance, buildings with 10,000 KLD per day and above.

For smaller scales, Ananth’s team believes, ASP and EA35 (Extended aeration technology) are best suited because it is a continuous process, ensuring treatment begins as soon as the sewage enters the tanks. In contrast, in SBR, a batch process, treatment is done in batches.

“So, it gets a little tricky in terms of synchronizing those batches. We have seen SBRs overflow because of a lack of synchronization, improper design and so on, where the raw sewage is overflowing into the streets. But at the municipal scale, SBR and MBBR is a beautiful technology since sewage entry is not as continuous as in smaller scale apartments and buildings,” says Janardhan Kodavasal, Vice President, Sales and Strategy, EcoTech.

MBR, on the other hand, requires a high level of automation to function and is installed in case of space limitations. The MBR membrane is extremely sensitive, requiring specialised training for safe installation. SBR is the most common type of STP model in Bengaluru, but it comes at a higher cost and requires extensive maintenance.

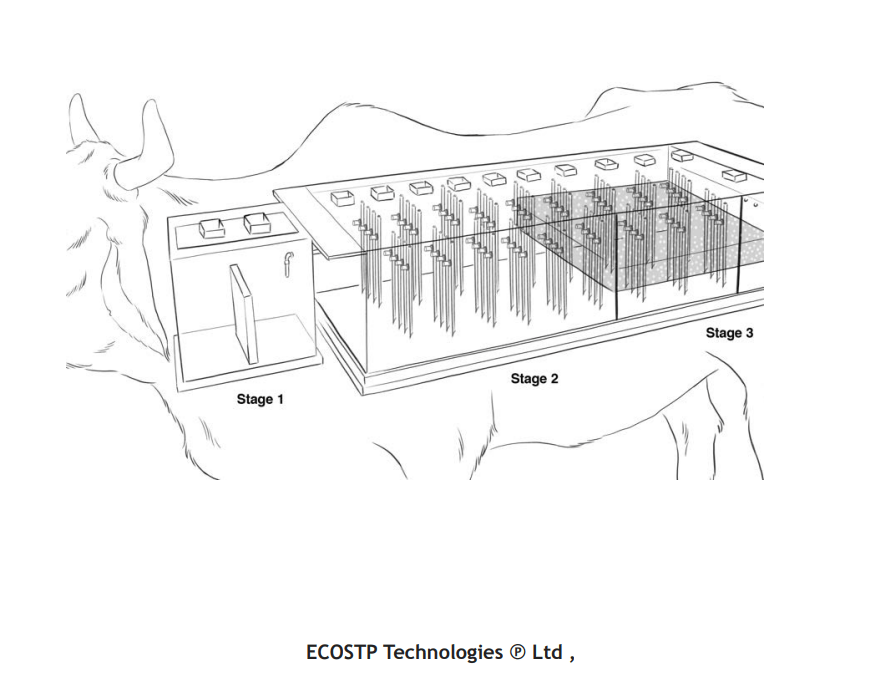

“One of the prime issues with aerobic STPs is that it needs expertise to maintain them, and Resident Welfare Associations (RWAs) are not properly equipped to do so, and not all apartments hire an agency for maintenance purposes,” says Tharun Kumar, founder and CEO of EcoSTP Technologies Pvt Ltd.

Rise of Anaerobic STPs

“85% of STPs don’t work in Bengaluru due to the huge costs they incur. Not all apartments have agencies to make them function, nor do they manage it themselves,” says Tharun.

Anaerobic treatment primarily relies on the natural processes of degradation without aeration. One challenge with this system is it requires a longer retention period and a lot of space. Since it is not a quick process, there is a need for several tanks to process the sewage water.

However, the anaerobic installers claim that their capital expenditure is about 15% higher than aerobic, due to more space and civil work, but their running cost is about 93% lower than aerobic STPs. There are no moving parts in an anaerobic STP, and the sludge is removed every two years through sucking and jetting.

Some service providers are also developing systems, which combine aerobic and anaerobic to increase efficiency and cut costs. At Aquasphere Greentech Solutions, they combine aerobic and anaerobic inside an SBR system. In Pratiks Enviro Solutions, to meet the PCB norms via anaerobic STPs, they provide a final tertiary treatment, which is an advanced oxidation technology with a carbon filter and ozone treatment.

As anaerobic STPs and their models become more prevalent, there is a growing need for increased awareness of their utility. “It’s more of a branding issue. There needs to be more talk on this technology for PCB to take notice as well,” says Tharun.

Are hassle-free STPs possible?

“You cannot manage an aerobic STP properly without a professional,” says Aditya Rao, founder and director of Greentivity Enviro Solutions. “Regular preventive maintenance and care are required on an hourly, eight-hour, daily, and weekly basis. However, most apartments only have pump operators for the task.”

While anaerobic systems provide convenient maintenance after installation, it is important to note that they also require an annual sludge cleaning process, which needs special skills.

Read more: Despite law prohibiting manual scavenging, practice rampant in the city

Ironically, in none of the models do experts claim the need for manual intervention for cleaning or treating the STP. If intervention is required, they promise high-quality Personal Protective Equipment Kits. However, the fatalities and injuries continue to be on the rise.

Another prime concern in the STP business is the restriction of promoting only one model per agency for their own advantage. Ideally, designers should consider the size of the apartment, retention period of the tanks etc., before finalising the STP model.

However, since each agency promotes one model, getting an objective view of the same is difficult. “Agencies do not want to acquire all the components and deal with the challenge of meeting different needs. So, they select a specific model and buy the components accordingly, and they keep promoting it,” says Srinivasan Sekar, water and wastewater technology expert.

The current challenge of apartments is recycling and reusing treated water. Only around 40% of the treated water gets reused for flushing, car washing, gardening and other apartment needs. However, the main concern is to manage the rest of the water.

“We did a hydrogeological survey and the assessment of the strata below the ground on different types of layers of the soil. STPs’ treated water cannot be unfiltered in the borewell. There is a process of contamination removal through the soil base, only after which it can be done,” says Dakshayini Dalvai, managing director at Pratiks Enviro Solutions.

She adds: “In anaerobic STPs, the partial recharge through soil base can be done without tertiary treatment and can be recharged to the ground. The design of the recharge or oxidation system depends on the type of soil base and can be customised.” Through this method, she claims, that complete treated water can be utilised within the apartment premises.

Although these service providers have a novel solution, the majority of the apartments continue to struggle to put the treated water to some use. They are requesting KSPCB to buy the treated water.

Better STPs can save lives

“99.9% of STPs don’t have any safety gear because people want to cut costs,” says Aditya. On one hand, there are unreported stories of BWSSB workers facing challenges without protective gear, on the other spectrum, human lives are being affected due to poorly-managed private STPs.

“Regulations are only specific to environmental laws, chemical content or biological content, but there is no information on how they should be cleaned or maintained,” says Siddharth K J, a member of Safai Karmachari Kavalu Samithi (SKKS), an organisation working towards complete eradication of manual scavenging. Operating STPs is a skill-based job. Appropriate training and safety gear should be compulsory. And for that to be implemented, STPs should be included in the Manual Scavengers Act.

Reporter’s diary:

Accompanying Aditya Rao from Greentivity Enviro Solutions, I was able to visit around eight STPs in both large and small apartments. While I was unable to visit an MBR and MBBR model, I was able to differentiate the quality of functioning between ASP and SBR. I must say, it is not as filthy and smelly as we assume STPs to be, if it is managed right.

If the right procedures are followed, from a bar screen till the final treated water tank, with a technician kept on duty at all times, the work of an STP is truly effective, in addition to not having any human intervention. Ultimately, it boils down to a few basic physics, understanding, management and, most importantly, willingness to manage STPs well.

We want to hear from you

- How are STPs managed in your apartment?

- What guidance/assistance would you require from the KSPCB to manage STPs in your building?

- Comment below or write to bengaluru@citizenmatters.in

Great job of compiling the STP technologies available today. It is a difficult space with little innovation and ready to be disrupted.

Sewage/sewerage (shit) management is a mega prob in mega cities. Complex issues need simple solutions. I have some simple, doable, economical, environmental and sustainable. Need somebody to carry forward this plan of action for creating a better world. I am 80 and live in Mysuru.