Chennai has seen rapid expansion in recent decades. But essentials such as water supply and sewage connections have failed to materialise in many parts of the city despite demand from residents. This has forced residents to find alternatives such as procuring water from tankers and setting up their own Sewage Treatment Plants (STPs).

Many apartments on the outskirts of Chennai, mainly on the Old Mahabalipuram Road (OMR), have set up STPs to treat the sewage generated in the apartment complex. Since the building rules mandate sewage treatment plants at multi-storeyed apartments, the builders will usually set up an STP and maintain them for a couple of years. Later, it will be handed over to the respective Resident’s Welfare Association (RWA).

Often, the challenge arises when the RWAs are left to manage the STP as maintenance is a costly affair given the need for continuous power supply, the appointment of staff and budgeting for their salaries. Besides, many residents are also against in-house STPs because of the foul odour that will be produced during the process of water treatment.

When the apartments hire sewage tankers to remove the sludge, it fails to serve the purpose as the tankers end up mixing the waste in the waterbodies or stormwater drains.

However, an apartment in Chennai’s Sholinganallur – The Central Park South, has set up a 135 Kilo Liters per day (KLD) STP in a way that they do not have to rely on the tankers to remove the sludge. The sludge is also recycled in-house making the apartment complex self-sustaining when it comes to sewage management. Notably, the STP also functions in a way that it is free from foul odour.

Here is a step-by-step process of how that STP works.

Read more: Within GCC limits since 2011, Thoraipakkam still waiting for piped water and sewage system

Functioning of STP in the Chennai apartment

The Central Park South has 172 apartment units in the complex. The STP setup caters to all the units and the treated water is sent back to the apartments for reuse for flushing.

The sewage from the toilets in the flats is collected in the primary collection tank. On average there is one such primary collection tank for every two blocks.

“It becomes a challenge when people flush all sort of things like sanitary pads and plastic wrappers into the toilets. It has to be mechanically removed. So we redesigned the particular portion in the tank and added the filters to sort out such waste materials,” says Rakesh Ohri, President of the Central Park South Owners Association.

The STP operators make their own mixed liquor suspended solids (concentration of suspended solids used in an aeration tank during the activated sludge process) using cow dung, jaggery and urea. Though there are suppliers for this, the operators here prefer to make their own concentration.

Monitoring mechanism of the STP

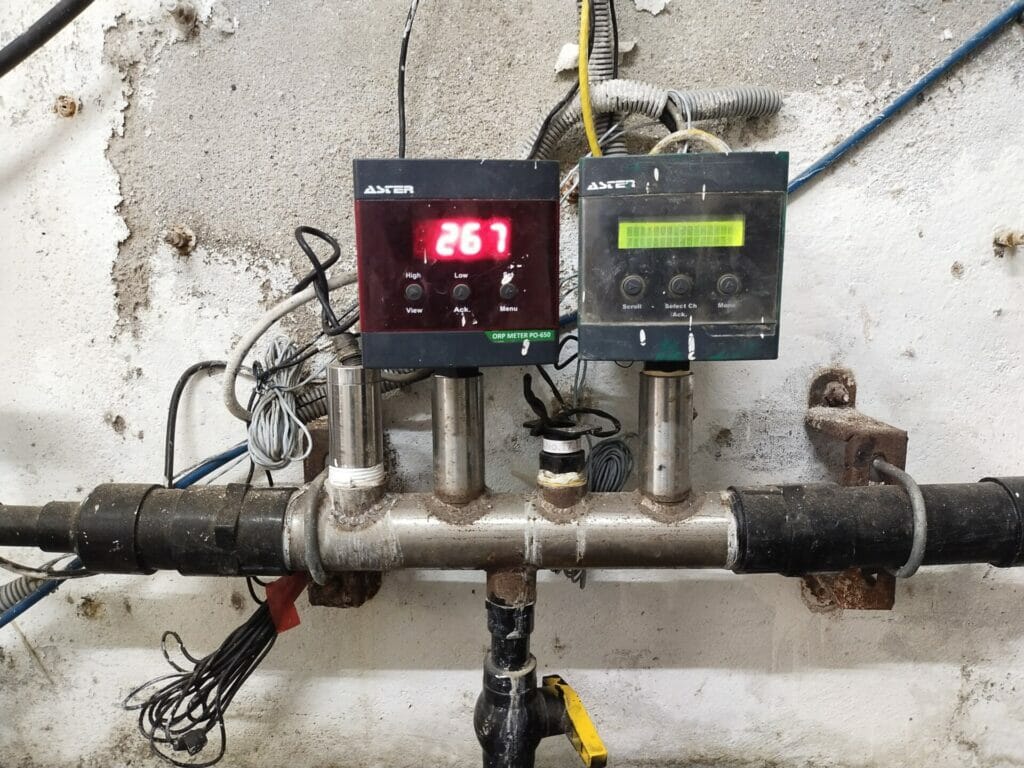

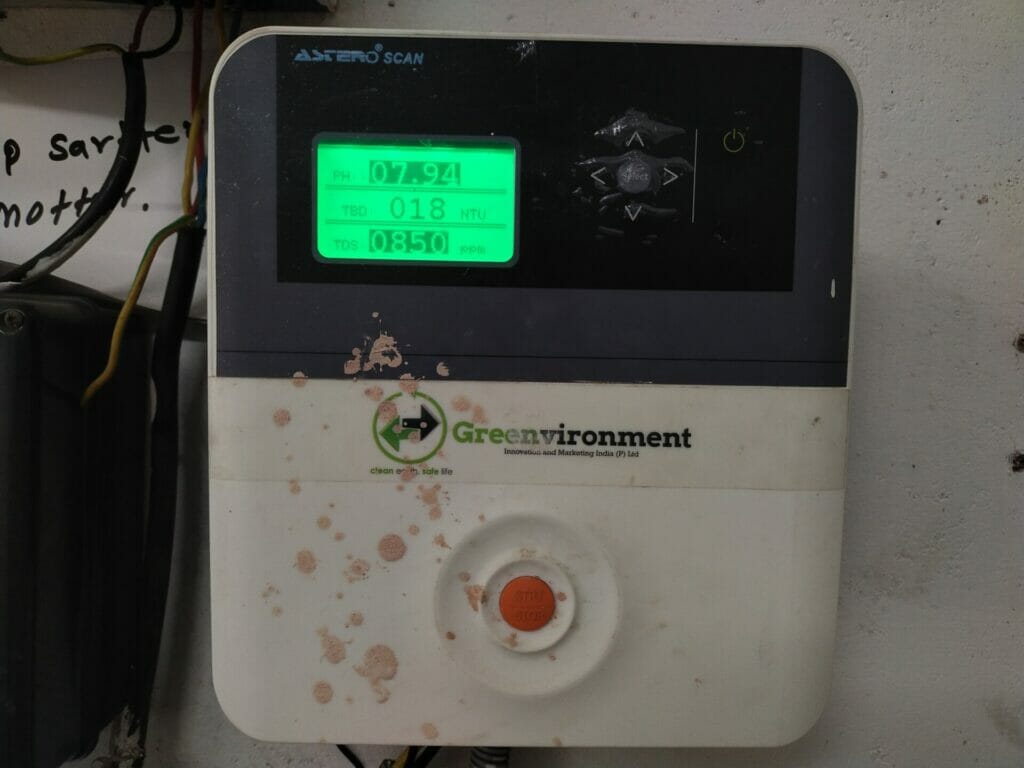

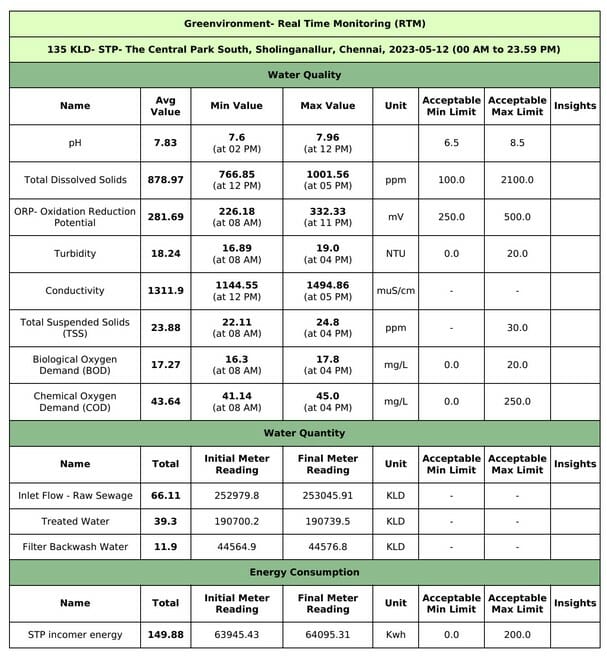

The STP is set up in such a way that the quantity, quality and power consumption are monitored throughout the process.

For the inflow of 05.31 m3/Hr, there was an outflow of 04.89 m3/Hr. “The remaining is the sludge. While most apartments use tankers to remove this sludge, we have redesigned the STP to pump back the sludge into the system and process it again. This way, there is no need for an external agency to remove the sludge,” says Rakesh, adding that this redesigned model is what makes the STP self-sustaining in their apartment in Chennai.

A contractor has also been hired for the installation and maintenance of the continuous online monitoring system. Accordingly, the daily reports on the water quality, quantity and energy consumption are sent to the RWA representatives, and they also have access to monitor the levels at any time of the day.

Roughly 20 to 25 units of power are used for STP alone. On average Rs 6,000 per day is spent on electricity. It is charged as per the standard common area rates according to the revised norms.

Including the staff salary, contractor online monitoring system, chemicals and other maintenance expenses, the apartment is spending around Rs 1.3 lakhs per month on the STP. This goes into the maintenance cost of the individual flats (172 flats) at 50 paise per square foot (average) rate.

Read more: Sewage lorries polluting Chennai lakes, drains with impunity

Challenges in maintenance of STPs in Chennai

Since the said apartment complex is in a low-lying area, it is prone to inundation even for a short spell of rain. Following the 2015 Chennai floods that damaged the STP set up in their apartment complex in Chennai, the RWA took the measures to set up underground tanks and diesel engine pumps to pump out the flooded water. They also revamped the STP by making some tweaks to the system.

“Over the years the functioning of STP has been stabilised. However, constant monitoring is a challenge. One of us in the team should keep a check on this and ensure things are in place on a daily basis,” says Rakesh, adding that appointing and retaining staff is another major challenge as they do not outsource the staff from an agency. Rather, they hire them directly.

Often, the major challenges in operating the STPs in such apartment complexes arise when the builder hands over the operation to the RWAs.

“Since RWAs are a small group of people who do not have the required skill set or knowledge on how to operate and maintain these STPs, they often end up shutting them down. This is where the Federation of OMR Resident Association (FOMRRA) comes in to aid the RWAs in guiding them with the right kind of vendors, staff, chemicals or other such needs,” says Harsha Koda, Co-founder of FOMRRA.

Harsha further adds that the cost of operation and maintenance of an STP in a small apartment complex (for example 50 dwelling units) will be around Rs 20,000 to Rs 30,000 excluding the electricity charges.

“The biggest challenge is in understanding how the technology works,” says Harsha. “There are grey water STPs (recycles water used in shower, dishwashing and kitchen sink) and black water STPs (recycles water used in toilet flush). One has to know the difference between such STPs and how it functions. There are enough resources now and the maintenance of an STP is not a major challenge.”

At times when Chennai is getting more high-rise buildings and water and sewerage management is becoming a challenge for the increasing population in the city, technology comes to our aid. The model adopted by Central Park South can prevent the illegal dumping of sewage in water bodies and ensure that the treated water is reused.

Would like to know more details as the same is very interesting and we have new products

Shobana Radhakrishnan article on ‘Chennai apartment Sewage Treatment Plant a self sustaining model to emulate’ was very useful. How to contact for more information?